The 3 Main Types of Woven Wire Mesh

Category

Related Posts

- August 31, 2020

- 8 min

Woven Wire Mesh

After understanding the distinction between Woven and Welded Wire Mesh, you might have chosen woven mesh for your project. Woven Wire Mesh demonstrates a flexible strength and a timeless aesthetic that makes it ideal for many different applications. If you selected a woven Wire Mesh, you may still be unsure about the different weave types to choose from. We invite you to follow along below as we guide you through our weave types and their benefits.

What Weave Types are Available?

For standard woven Wire Mesh products, there are three main weave types to choose from: Plain, Lock Crimp, and Intercrimp.

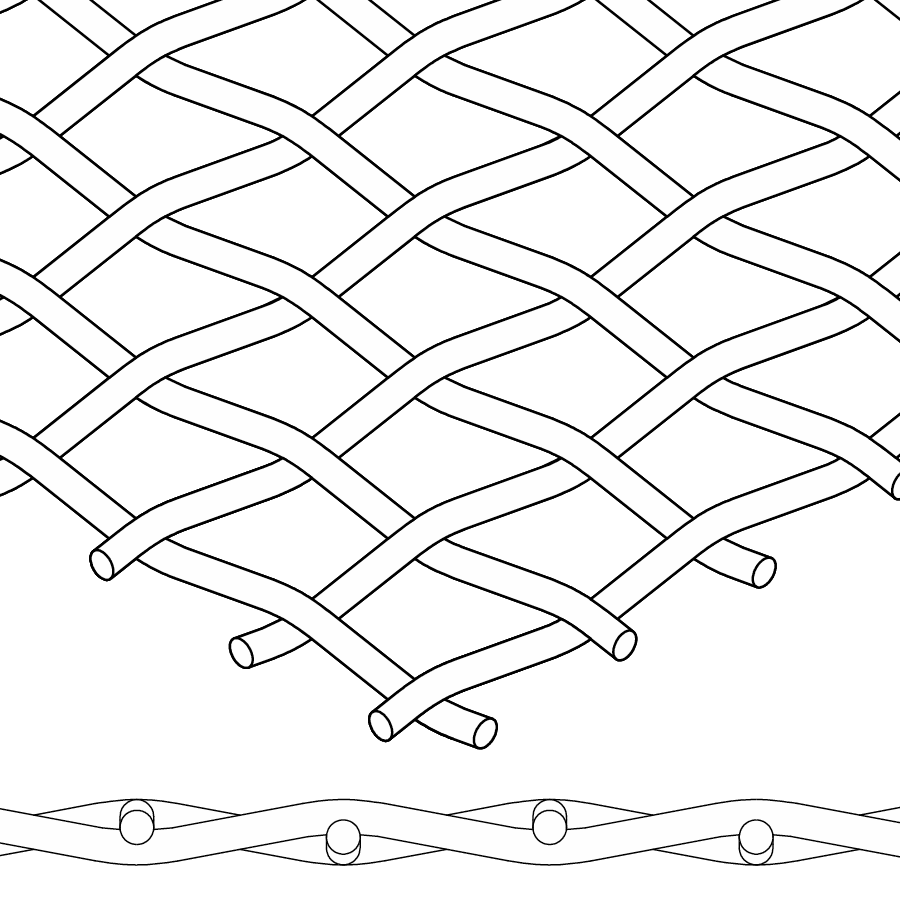

Plain Weave Wire Mesh

Plain Weave Wire Mesh is a traditional weave formed with straight warp wires and fill wires assembled in a simple over, under weave. The resulting product will exhibit a simple appearance with a relatively smooth surface. People often use plain weaves in Wire Mesh items with a higher mesh count. It is likely that many of the wire cloth items you encounter in daily life will exhibit a Plain weave.

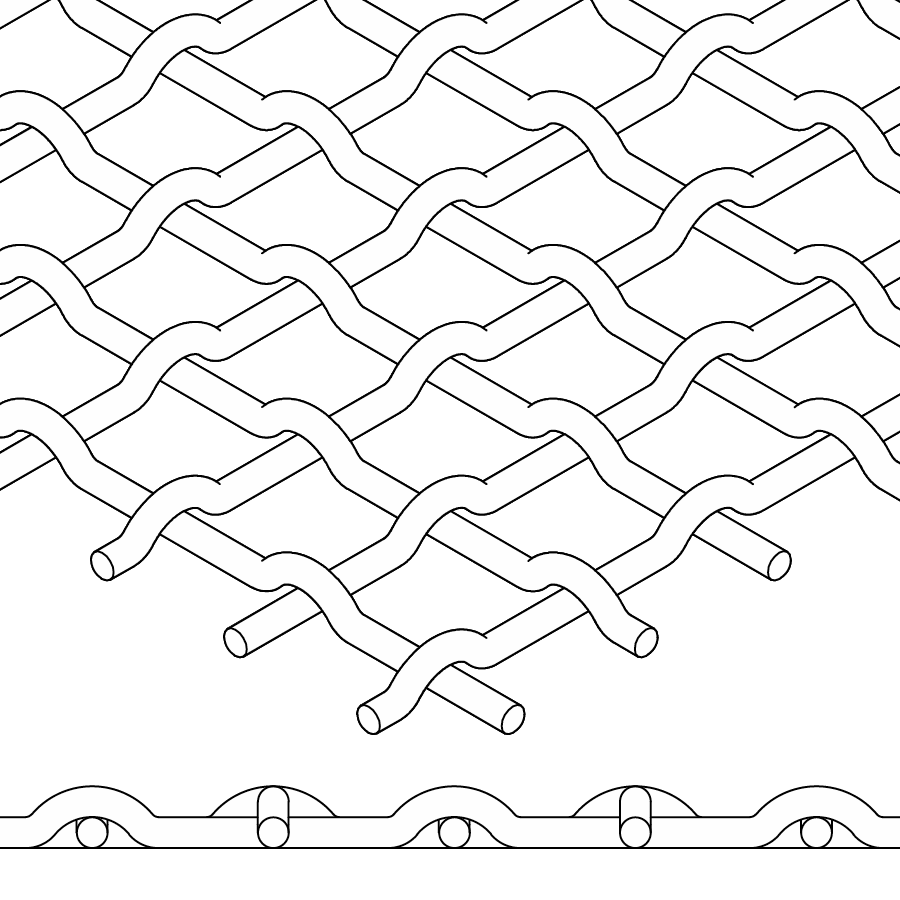

Lock Crimp Wire Mesh

Lock Crimp Wire Mesh also features straight wires assembled in a classic over, under configuration. However, this mesh features a pinched or locked section of wire at each intersection. As the wires in one direction weave above or below perpendicular wires, they mechanically form secure "bumps" and "reverse bumps."

The locked wires create additional rigidity and security to prevent shifting or separating. You may hear of another type of weave known as Flat Top. This is a slightly altered version of a Lock Crimp where all the bumps are on the same side of the sheet.

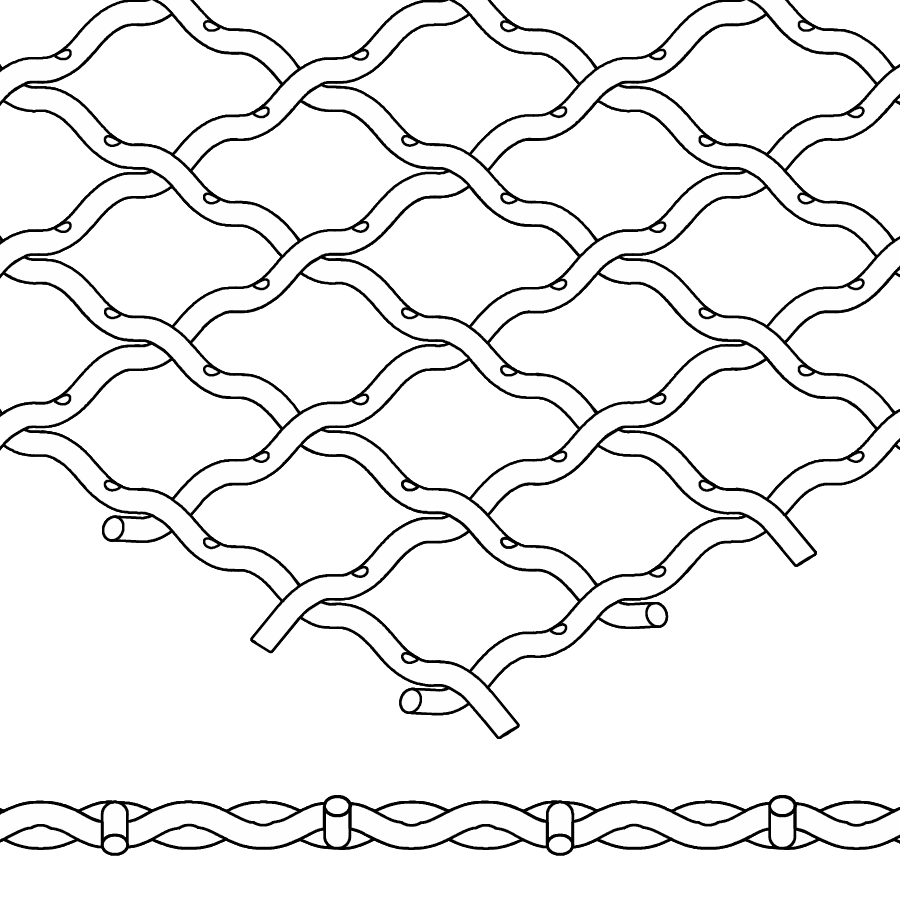

Intercrimp Wire Mesh

Intercrimp Wire Mesh crimps the wires in a zig-zag fashion. When weaving it into a Mesh, each wire intersection will have several crimps. This texture creates a heightened grip between the crossing wires, therefore adding rigidity. In addition to helping the wires stay in place, these crimps add a unique visual interest.

What Wire Mesh is the Sturdiest?

Lock Crimp is the sturdiest option among these weaves. Because the pinched intersections resist forces attempting to spread the wires. For this reason, Lock Crimp is a favorite for security applications and Infill Panel railing inserts.

Following Lock Crimp, Intercrimp also provides an elevated level of strength. It requires a more concentrated effort to shift the wires than a Plain weave.

What Designer Woven Mesh is Available?

Designer Wire Mesh features woven wires that form unique designs and add an unforgettable look to everyday applications. Within our Designer Wire Mesh selections, there are 28 eye-catching weaves to choose from. These include triple-shute, rigid cable-style (AURA™), helical (HALO™), and many more. For a full list of our decorative weave types, we invite you to browse our Designer Wire Mesh inventory.

How to Specify and Order Woven Wire Mesh

If you need woven Wire Mesh, McNICHOLS has a large selection for a variety of applications. To choose Wire Mesh, use our guide to determine the requirements for your product. Our woven products, including Welded Wire Mesh, are strong, attractive, and versatile for various uses in your next project!

We are Inspired to Serve® you at 855.318.8791, [email protected], or via Live Chat on mcnichols.com.