Custom Perforated Metal Façade is the Main Attraction at Tampa Museum of Art

- October 26, 2020

- 8 min

The Hole Challenge for the Tampa Museum of Art

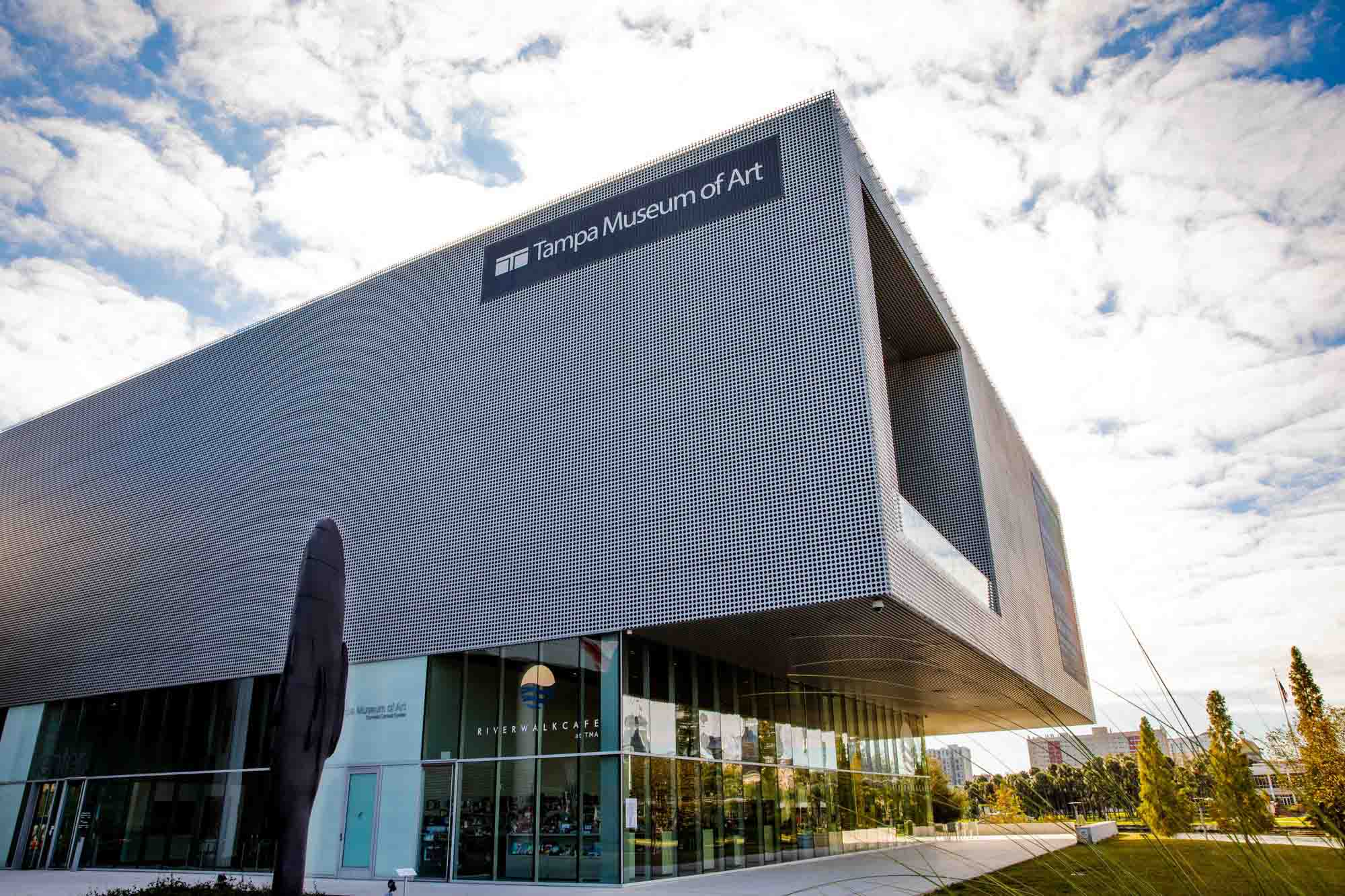

The Tampa Museum of Art, founded in 1920, is a center that inspires, engages and educates with its masterpieces. Nearly 90 years after its founding, the museum was looking to upgrade to a building fitting of the art it displayed.

Renowned architect Stanley Saitowitz agreed to take on this complex task. His goal was to create a beautiful but neutral edifice—a jewel box that would entice while still allowing the art pieces to shine.

Another goal was to reflect the building's surroundings. Located in the heart of downtown beside the Curtis Hixon Waterfront Park and sitting on the Hillsborough River, the structure would ideally connect to and amplify the Tampa environment.

The Hole Solution for the Tampa Museum of Art

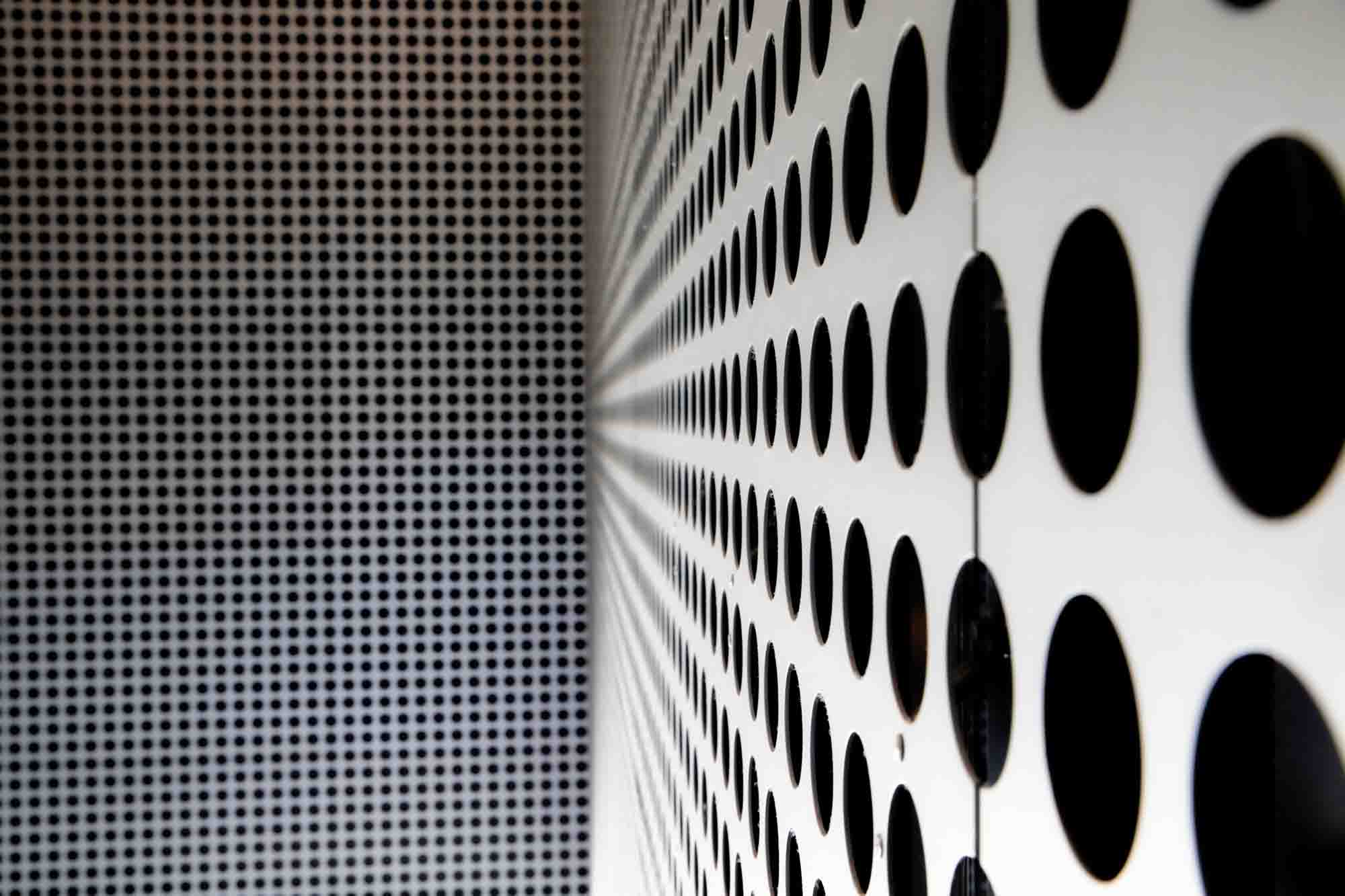

A custom McNICHOLS® Perforated Metal brought these visions to life. Unique perforated panels with 3″ round holes would clad the new structure's exterior to create a shining architectural landmark. These large openings were arranged in a straight row with centers 4″ apart on a .1250″ (8 gauge) thick sheet.

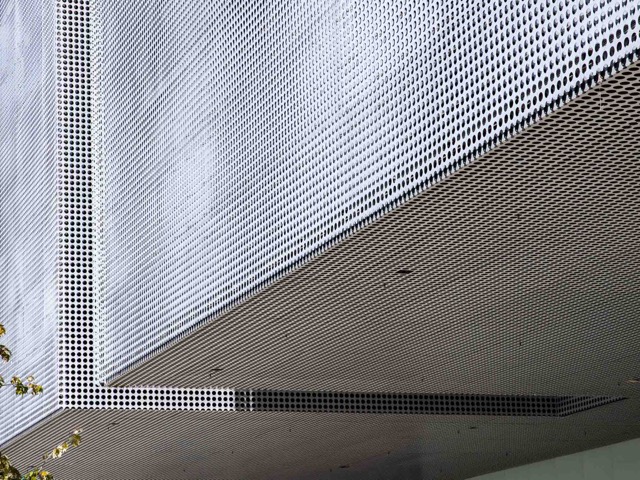

Superior durability and a lightweight yet strong construction made Aluminum an ideal material choice. Anodized and clear-coated for a satin polish finish, the panels resist corrosion and require little maintenance, despite the area's waterfront location and variable weather conditions. A single lot of Aluminum had to be obtained to ensure a uniform appearance for each panel. Depending on the makeup of the Aluminum batch, the anodizing process could produce differing shades. By ordering from the same material group, the team could be confident that each sheet was just right!

The designers ultimately decided that Perforated Metal would better suit some trickier installation requirements, although they considered economical Expanded Metal for this dazzling façade.

A Precise Preparation

The team needed thousands of perforated panels to cover the exterior. While still desiring the appearance of one seamless, uninterrupted skin. Fabricators carefully cut the sheets so that the large openings would line up when placed side by side. If the shear cut through one line of holes, the sheet set beside it would connect where the pattern left off. Although it required detailed planning and measuring, it would be well worth it for a flawless result!

This was not the only precaution taken to guarantee perfection. In each step of the process—from fabricating to packaging to installation—delicate handling was paramount. Any scratches on the material would require throwing out the panel altogether. McNICHOLS packaged each pallet with the utmost care, placing paper between each metal sheet and securing the edges from damage.

As a final safeguard, the team decided not to keep the material at the job site, instead delivering the sheets only when it was time to install that section. By keeping the Perforated Metal at the nearest McNICHOLS® Metals Service Center until needed, we protected the material from damage and theft.

The Moiré the Merrier

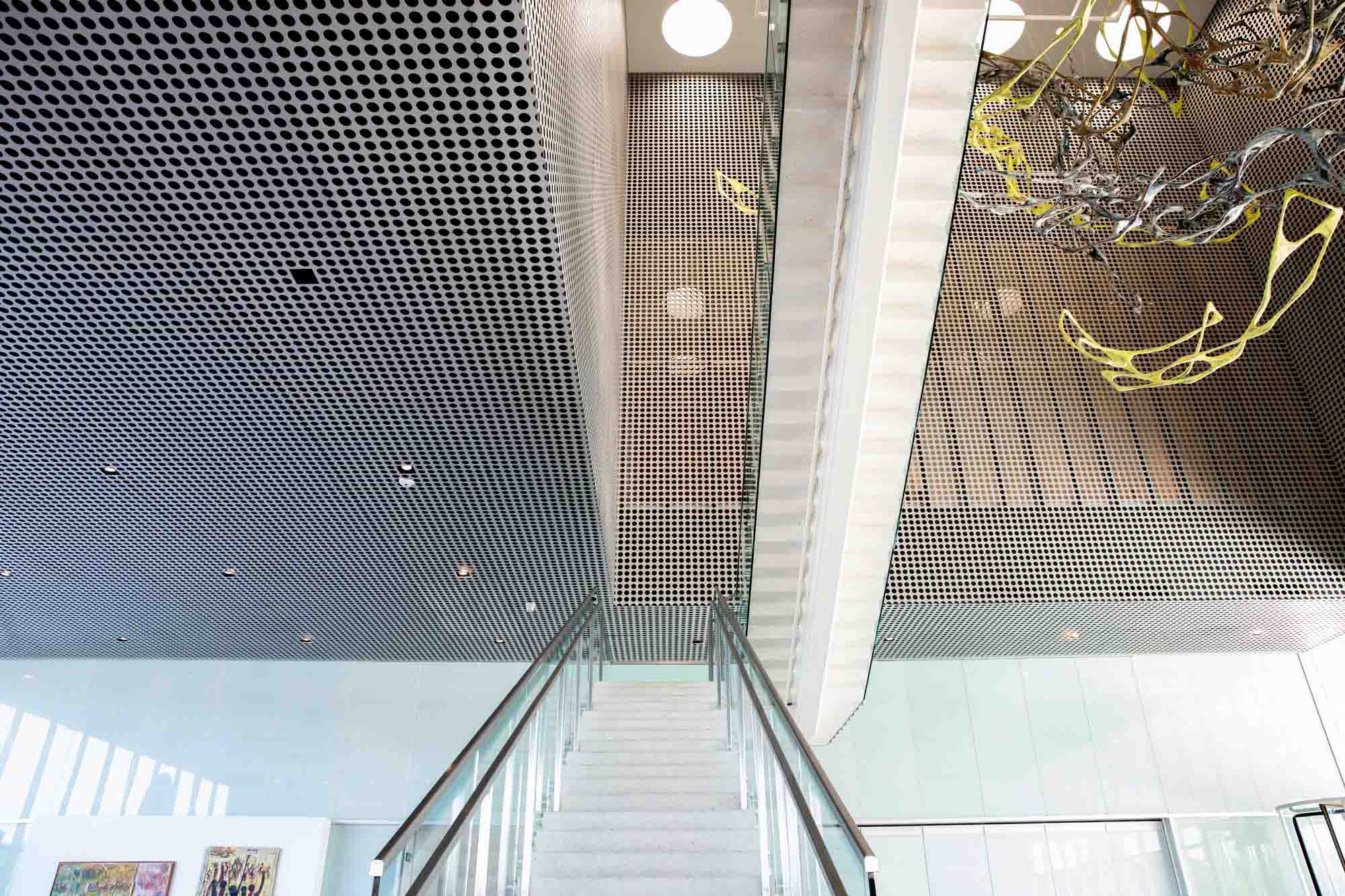

Taking the museum's metal encasement one step further, the team decided to install not just one but two Perforated Metal layers. The layers were installed 5″ apart in a slightly offset placement, establishing a unique visual effect called a moiré pattern. This strategy adds dimension and interest in a geometric optical phenomenon—much "moiré" than meets the eye!

As a finishing touch, LED lights were placed in between these layers on the south façade. At night, 14,000 square feet of illumination dance between the openings of the shimmering metal. The light show would proudly identify the museum among the bustling downtown with an unexpected exterior art installation.

The Final Masterpiece - the Tampa Museum of Art

Altogether, around 4,000 panels were used, donning the building in a total of 1 million holes. After the façade entices museum visitors inside, the Perforated Metal continues to welcome them in as it stretches across the ceiling and extends onto the walls.

They debuted the completed building to the public on February 6, 2010. Sitting among the Waterfront Arts District of Tampa, Florida, the completed museum stands as an iconic landmark, inspiring design piece and favored photo backdrop for visitors from near and far.

Beyond its own beauty, the reflective metal also enhances the surrounding charm. Saitowitz notes, "The building is not only in the landscape, but is the landscape, reflecting the greenery, shimmering like the water, flickering like clouds. It blurs and unifies, making the museum a park, the park a museum."

Following its reveal, the innovative 66,000-square-foot structure won awards from several organizations, including the American Institute of Architecture. With its inspired design and choice of materials, the museum appeals to patrons, park visitors, and passersby alike—standing as a beloved community fixture and shining symbol of creativity.

If you are interested in the Perforated Metal used in this project, contact us at 855.318.8791, [email protected], or via Live Chat on mcnichols.com.