Bar Grating End Banding: The Difference Between Load & Trim?

- October 12, 2020

- 8 min

End Banding Process - Bar Grating

There are several factors to consider when choosing the right Grating for your project. After you’ve selected the Grating that suits your application best, there are a few finishing touches that can prepare your panels for their final application.

One of the last steps is called bar grating end banding. This involves welding a Flat Bar to close open bearing bar ends. This gives your Bar Grating a uniform look and increases its construction strength.

Customers often ask us about the specifics of end banding, including the difference between load and trim banding. In this article, we detail banding options as well as how to maximize the stability and appearance of your Grating selection.

What is Bar Grating End Banding?

With Bar Grating products, end banding is a process that brings uniformity to all sides of a piece of Grating. To start, cut a Flat Bar with the same primary material, height, and thickness as the selected Grating bearing bars to match the width of the panel or piece(s). Next, weld the Flat Bar to open bearing bar ends and/or cut sections of the Grating.

There are several reasons to choose to band your Bar Grating pieces. The banding process adds an overall finished appearance and can prevent bearing bars from warping over time. Depending on the final application and intended use of the Grating, two banding methods can be employed: load banding and trim banding.

Load Band

A load band welds the Flat Bar to the open (unfinished) end of every bearing bar on a piece of Grating. This process locks the bearing bar ends in place, preventing them from bending and twisting under force.

In trench grating applications that bear a significant amount of weight, people commonly use load bands. For example, people often use this method in places where they expect heavy vehicular traffic, such as automobiles and forklifts. If wheels frequently go over the Grating, load banding helps the bearing bars withstand repeated pressure, ensuring their strength.

In high-loading environments, people often choose load-banding Steel Bar Grating because of its strength and durability. Typically, Aluminum Grating does not support heavy loads over large areas. Therefore, load banding is unusual for this material type.

Trim Band

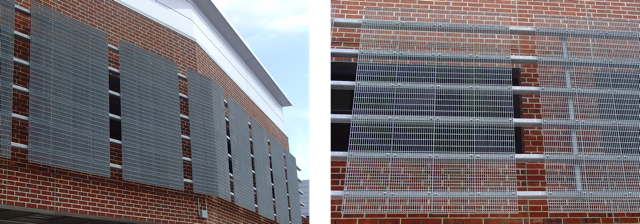

When selecting trim banding, we weld the Flat Bar to the corners and to every fourth or sixth bearing bar, depending on the overall width of the piece. Unlike a load band, you wouldn't typically select trim banding for an application designed to carry a heavy load. However, trim end banding does improve your product’s appearance and enhances its stability. This banding method is most commonly used in pedestrian traffic applications where vehicular traffic and loading is a non-factor.

Our Fabrication Services

So, should you close up those open bearing bar ends with a Flat Bar in a trim or load band? If you’re not sure, no worries! McNICHOLS is here for you. In fact, if you would like assistance with bar grating end banding, our fabrication specialists are ready to serve! At our Metals Service Centers, we are eager to help you save time and resources with our fabrication services, including cutting your panel to size, welding and other finishing touches.