Enhancing EV Charging Stations with Perforated Metal

- June 28, 2023

- 5 min

Electric Vehicle Charging Stations

Electric Vehicle integration refers to incorporating electric vehicles into various aspects of transportation, infrastructure, and energy systems. This incorporation of Electric Vehicles EVs is a crucial aspect of the alternative energy revolution. As the demand for EVs continues to rise, the development of efficient charging infrastructure becomes paramount.

Electric vehicles require a robust network of charging stations and infrastructure. These EV Charging stations provide convenient and accessible charging options that efficiently use energy resources. Within this context, the use of Specialty Metals in the design and construction of Electric Charging stations plays a significant role.

EV Charging Stations and Specialty Metals

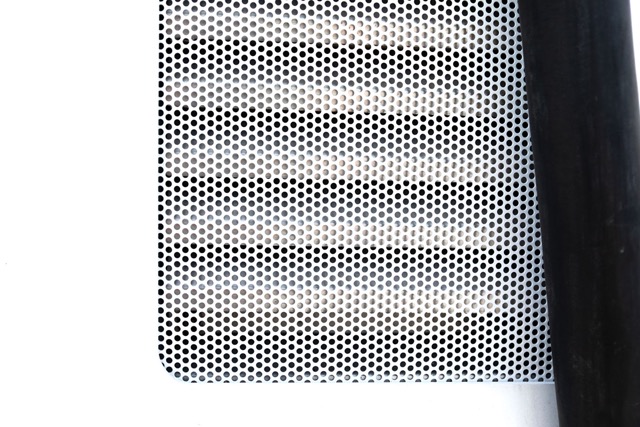

When developing Electric Vehicle (EV) charging stations, electric vehicle manufacturers utilize Specialty Metals for functionality while still providing an aesthetic appearance. McNICHOLS® Perforated Metal is the perfect example of a Specialty Metal that meets those requirements.

Perforated Metal is a versatile material that finds utility in various applications, including Electric Vehicle (EV) Charging stations. It is used in EV Charging stations for its unique characteristics and benefits. The perforations allow for enhanced airflow and ventilation, promoting effective heat distribution from the charging equipment.

EV Charging stations often generate significant heat during the charging process. The perforations are crucial in preventing the overheating of the equipment and ensuring the longevity and performance of the charging infrastructure.

Additionally, Perforated Metals adds an aesthetic appeal to the overall EV charging station design - complementing the modern, sleek, and sophisticated appearance. Perforated Metal panels can be powder-coated or painted to add an extra aesthetic element and offer a more finished look.

Overall, the use of Perforated Metal in Electric Vehicle Charging Stations serves both functional and visual purposes. It provides efficient cooling and an attractive look to support the growing electric vehicle infrastructure.

Featured Products and Benefits

EV charging station applications utilize a wide range of sheet products and even gratings. A common Hole Product used is McNICHOLS® Perforated Metal, Round, Aluminum, Alloy 3003-H14, .0320" Thick (20 Gauge), 1/8" Round on 3/16" Staggered Centers, 40% Open Area. The material type, gauge, or open area may vary depending on the application or desired aesthetic appeal.

Some benefits Round Perforated Metal provides to Electric Vehicle Charging stations include:

- Enhanced Ventilation

- Heat Dissipation

- Structural Strength

- Aesthetically Pleasing

- Customization Options

- Durability and Longevity

We invite you to learn more about McNICHOLS® Perforated Metal and other Specialty Metals and Gratings. We are ready and Inspired to Serve® you at 855.318.8791, [email protected], or via Live Chat on mcnichols.com.