Difference Between Ferrous and Non-Ferrous Metals

- February 2, 2022

- 8 min

Ferrous vs. Non-Ferrous Metals

Humans have been using different types of metals for thousands of years. Over time, our expertise and understanding of these metals have greatly increased. We now understand the atomic makeup of the metal elements found on the periodic table. We also know which of those combine to make the common metal alloys that we use today.

One characteristic that we use to distinguish metals is whether or not they contain iron. Ferrous metals have iron in their makeup. Whereas, non-ferrous metals have no iron. In this blog, we will discuss the similarities and differences between ferrous and non-ferrous metals.

What Are Ferrous Metals?

Simply put, ferrous metals contain some amount of iron. In fact, the very word "ferrous" comes from the Latin word, "ferrum," which means "contains iron." Also of note, the periodic symbol for iron is Fe.

As you can imagine, there are many kinds of ferrous metals, including iron and steel. This includes variations such as cast iron, wrought iron, stainless steel, carbon steel, and so on.

What Are Non-Ferrous Metals?

Non-ferrous metals are those metals that contain no iron, with aluminum being the most common. Other non-ferrous metals and metal alloys are bronze, brass, copper, tin, silver, gold, and platinum.

We rely on non-ferrous metals very heavily in different ways. Because aluminum is so lightweight, for example, we use it to build aircraft. Another great example is copper. It is both ductile and highly malleable, which makes it ideal for pipes, bearings, sheet roofing, and so much more.

The Differences Between Ferrous and Non-Ferrous Metals

We have already covered the primary difference between these metals. Concisely put, ferrous metals contain iron and non-ferrous metals do not.

However, it is worth noting that different types of metals can have similar characteristics, too. Depending on your project requirements, you may rely on either ferrous or non-ferrous metals. Your decision will depend on the special properties they each bring to the table.

It's important to understand what these different properties are and how they factor into your project or application. Keep reading to learn more about key differentiators!

Magnetic Properties

Another major distinction between these types of metals is their magnetism. Most ferrous metals are magnetic whereas non-ferrous metals are NOT magnetic. This is one of the reasons that we rely on ferrous metals so much for our different needs.

For example, these magnetic properties make ferrous metals invaluable for our different motorized and electrical appliances. We also need them for simple magnets. The next time you use a magnet to put a reminder on a metal surface at work, keep in mind that it is a ferrous metal that is making that happen. Check out how the U.S. Army uses ferrous metals in their trade show booths.

You don't always need metal with magnetic properties. This is why we use non-ferrous metals for various wiring and electrical application needs.

Resistance Properties

One of the biggest concerns about any project is how well it will resist things like rust and corrosion. These concerns become crucial when your project will be outdoors for an extended period or exposed to the elements.

Which metal should you rely on to fight off rust and corrosion? Generally speaking, non-ferrous metals offer better resistance because they have no iron. It is no coincidence that so many gutters and roofs rely on non-ferrous metals!

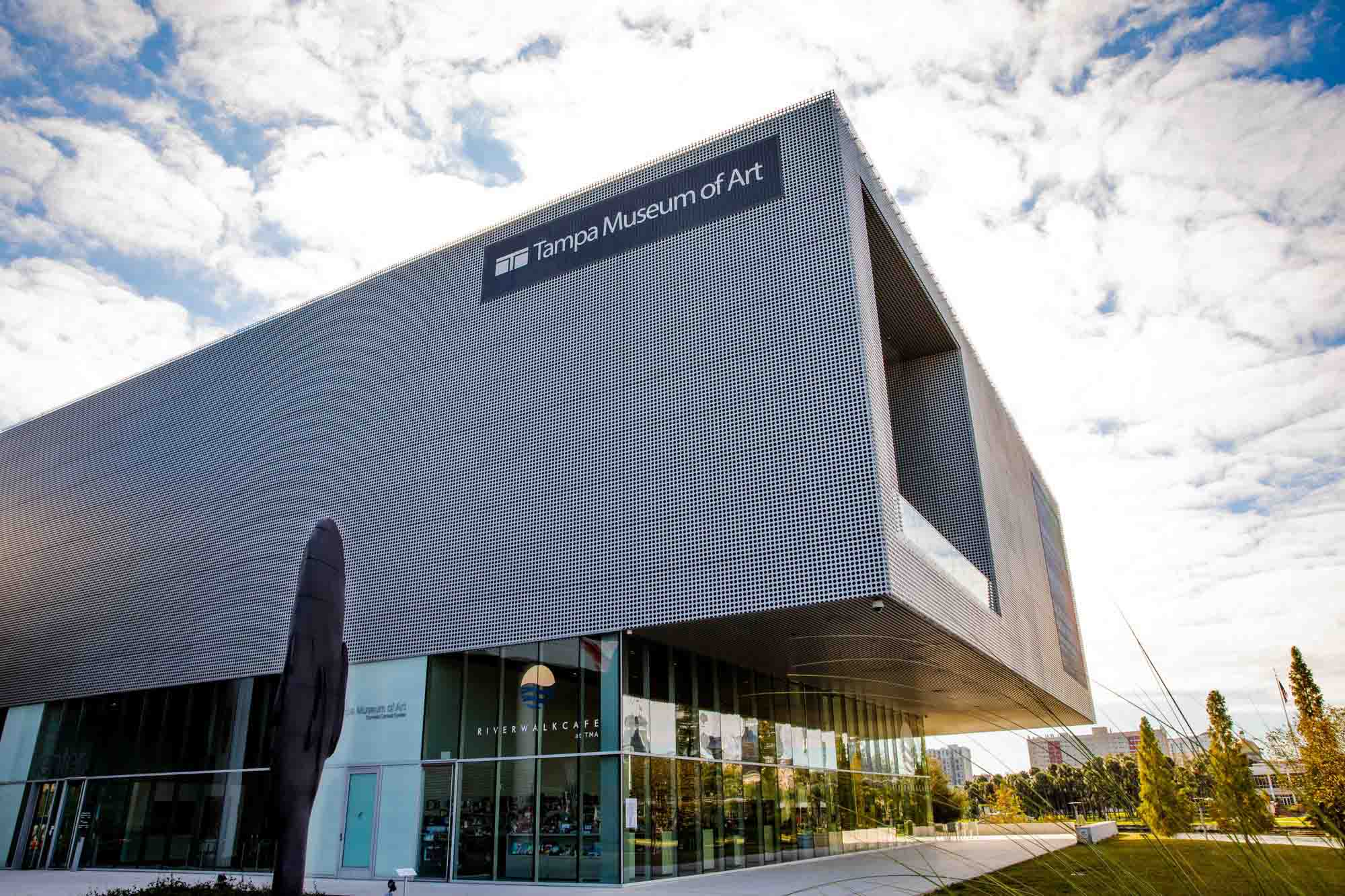

One extraordinary example of using non-ferrous metals for an outdoor structure is the Tampa Museum of Art. The exterior of the building utilized over 4,000 panels of custom Aluminum Perforated Metal.

Two exceptions to the resistance rules are stainless steel and wrought iron. These ferrous alloys actually contain enough iron to ward off rust very effectively. Other ferrous metals, though, have just enough iron to make themselves more vulnerable to rust and corrosion.

Weight and Cost

The final factors you need to be concerned about for your project are weight and cost. So, how do these metals compare?

Generally speaking, ferrous metals are heavier than non-ferrous metals. This is probably not surprising as the iron content makes these metals much heavier.

In terms of cost, non-ferrous metals are typically more expensive than ferrous metals. Why? Supply and demand. Not only is there less non-ferrous metal available, but the demand is usually higher than ferrous metal.

McNICHOLS is the leading supplier of Specialty Metals in the United States. To discover how we can bring your next project to life, please contact us at 855.318.8791, [email protected], or via Live Chat on mcnichols.com.