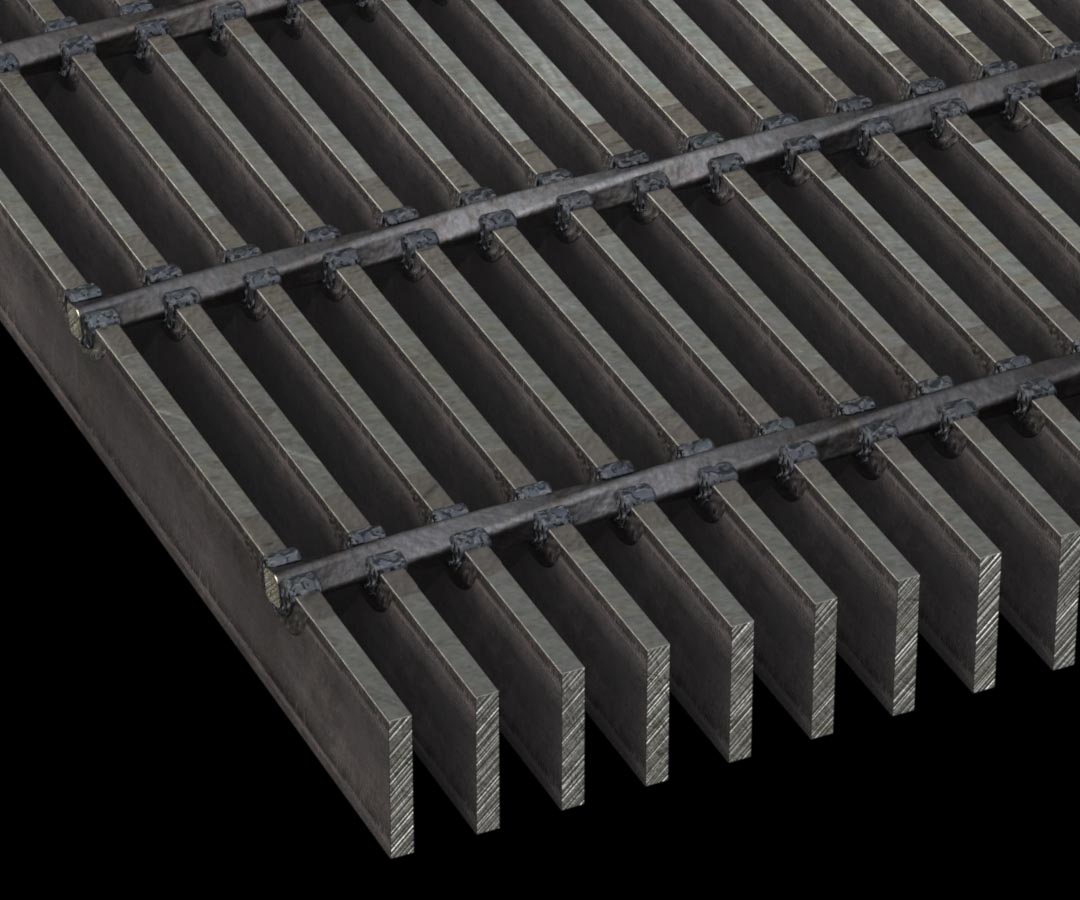

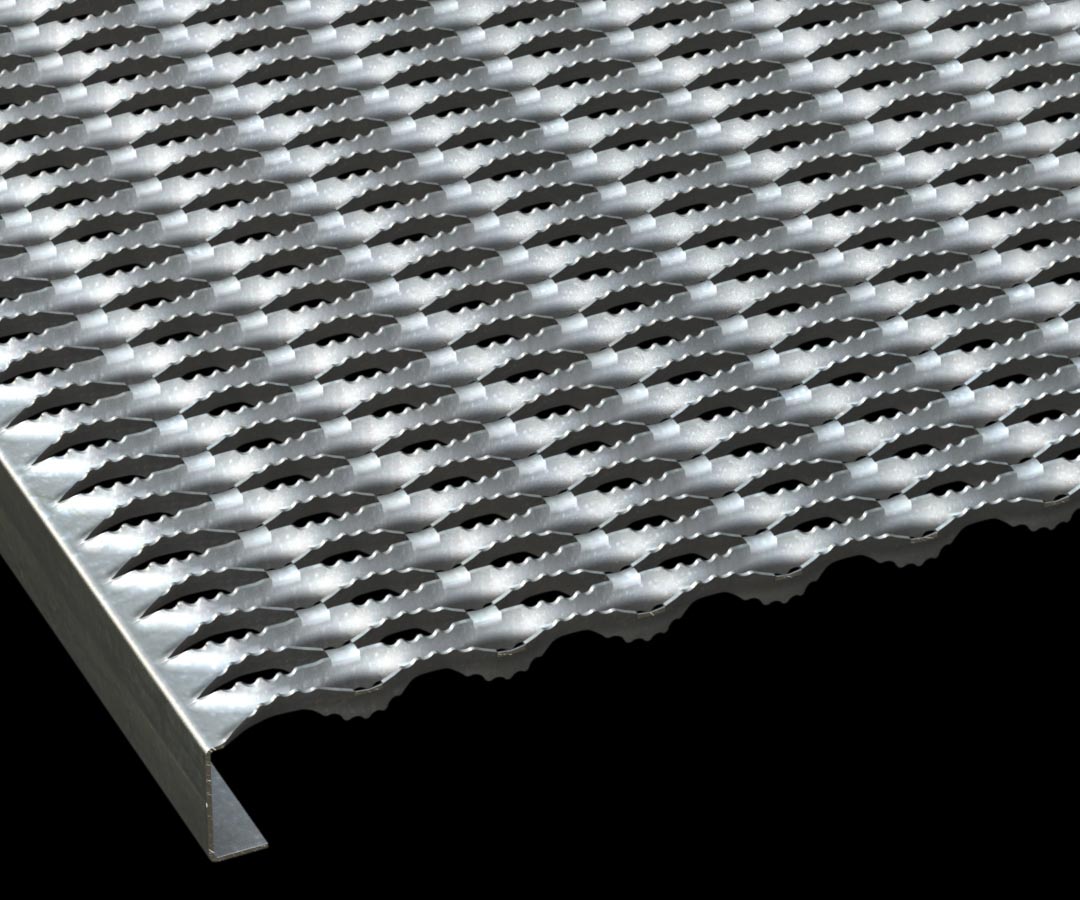

Versatile Applications & Reliable Durability of Plank Grating

McNICHOLS® Plank Grating offers robust support and ventilation, making it ideal for industrial platforms, walkways, and Stair Treads. Heavy-duty Planks withstand heavy loads and harsh environments, ensuring safety in factories, warehouses, and outdoor settings. Plank Grating is also utilized in applications for architectural designs, adding both functionality and aesthetic appeal to all types of structures and landscapes.

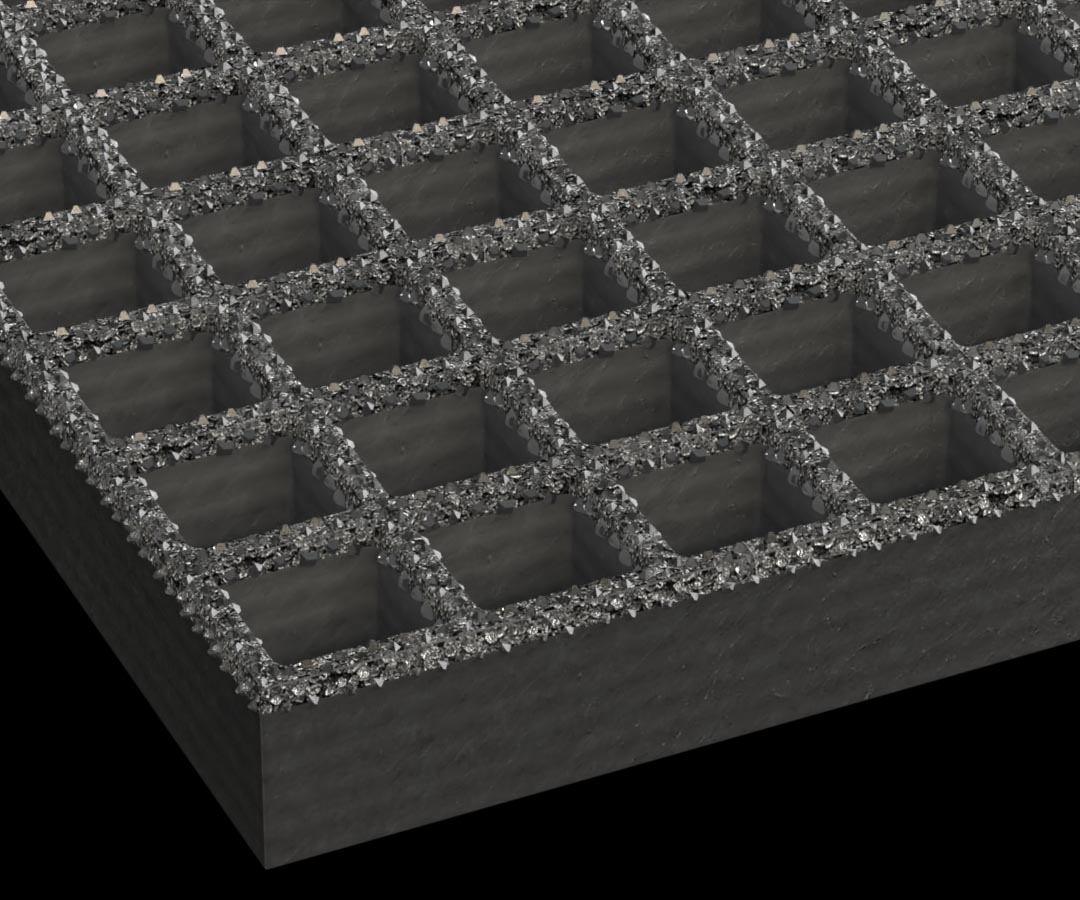

Specialty Metals & Fiberglass In-Stock Nationwide

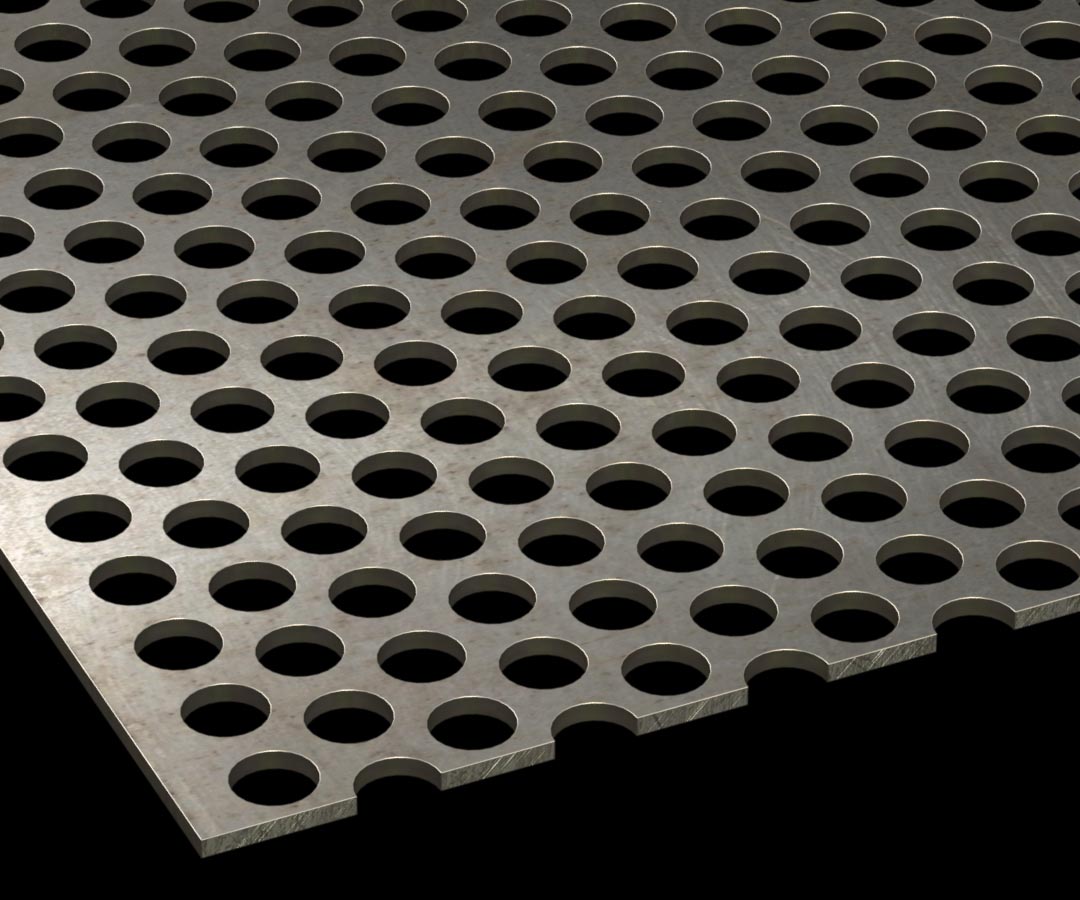

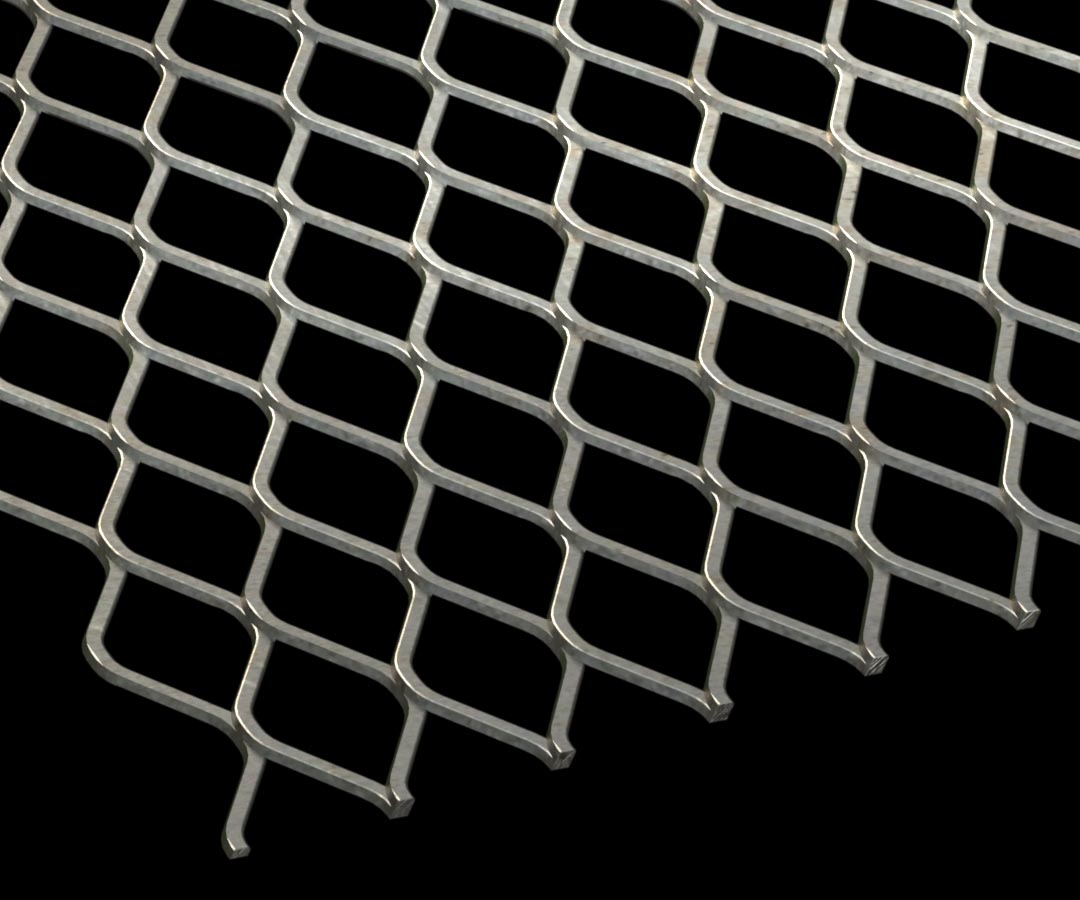

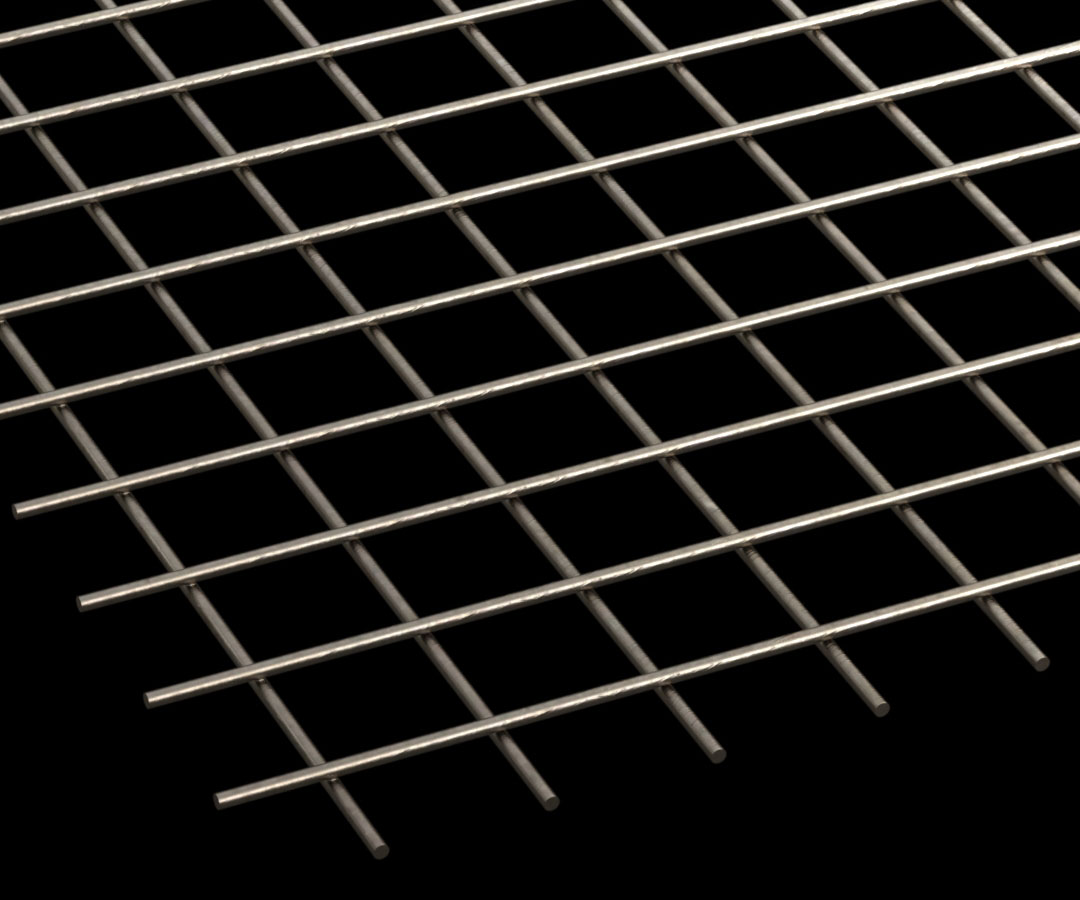

McNICHOLS is the leading supplier of Specialty Metals and Fiberglass including Perforated Metal, Expanded Metal, Wire Mesh, Grating, and Flooring products. With 19 locations nationwide, our team of knowledgeable associates are ready and Inspired to Serve® you!

National Welding Month Giveaway

In celebration of welders nationwide, we are excited to announce our National Welding Month Giveaway! This month, lucky participants have the chance to win a cutting-edge branded Lincoln Electric VIKING 3250D FGS Welding Helmet, marked by its advanced features and superior protection—an estimated value of $667. Enter now for a chance to win!

Hole Product Catalogs

Learn about McNICHOLS® Hole Products and Value-Added Services, as well as extensive technical guidance and ordering information.

The Hole Story®

Read the story of Bob McNichols' survival and how he grew McNICHOLS from a small family business into a national company and industry leader.

Hole Product Ideas

Be inspired by others' creative use of McNICHOLS® Hole Products in our collection of product application case studies.

19 Locations

Our friendly, knowledgeable associates are ready and Inspired to Serve® you at one of our 19 Metals Service Centers across America!

Designer Metals

Available in a wide variety of materials, styles, patterns, and finishes, the complete line of McNICHOLS® Designer Metals are unforgettable!

Serving Here

Explore our Careers page for an insight into what it's like to be a "Hole Team" member and find out if the McNICHOLS culture is the best fit for you.

Thanks for visiting mcnichols.com!

After surviving a plane crash during World War II and spending six months in a German prison camp before he was liberated, Robert L. "Bob" McNichols founded McNICHOLS CO. in 1952. With the support of his wife Phyllis, the small family business began to form. My grandpa would take orders by phone in the morning and make deliveries in the afternoon – in his station wagon. In the evening, you could find him in the living room finishing up paperwork that accompanied running his own business. Customers did not have to trust him – but they did. He was an honest man, always striving to do what he said he would do. His "hole" life was centered around one thought: serving others.

My father Gene joined the family business after going to school and serving in the United States Air Force. With the unfortunate loss of Bob to cancer in 1981, Gene fully assumed the reigns of McNICHOLS and took the Company national by adding Metals Service Centers in many of America's largest cities. Today, we are blessed to serve our customers from 19 locations across the nation.

Today, we still have one goal in mind: service. In fact, our associates (we refer to them as the "Hole Team") are obsessed with it. We believe our culture of being Inspired to Serve® is genuine and consistent. If you have given us an opportunity in the past, we trust you have experienced it. We don't always get it right, but we will do our best to make it right.

To earn your business, we are fully aware that you need solutions rapidly. We also believe that exceptional service should be at the core of your experience. Should you choose us, we will treat you like you deserve and do what we said we would do – just like grandpa used to do.

Scott McNichols

Learn More About Our Hole Commitment

The Hole Team strives daily to achieve the goal of providing customers with Superior Service, Quality, and Performance… That's The Hole Story®! Our associates are guided by our HOLE CALLING, believe in our HOLE PURPOSE, and honor our HOLE FOUNDATION that was put in place by our Founder, Robert L. "Bob" McNichols in 1952.